astm tear testing|tear initiation strength test : private label 5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action. A strategy deemed safe, affordable and sustainable was adopted to autoclave and re-use gowns based on a risk-stratified approach.

{plog:ftitle_list}

If you prefer to autoclave, instruments may be autoclaved individually or in sets. Disposable paper or plastic pouches are ideal for autoclaving individual instruments. Use a pouch wide enough for instruments with ratchet locks, .A key component to understanding what can and cannot be autoclaved is whether or not the material can withstand the pressure of an autoclave’s sterilization cycle.

5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service .

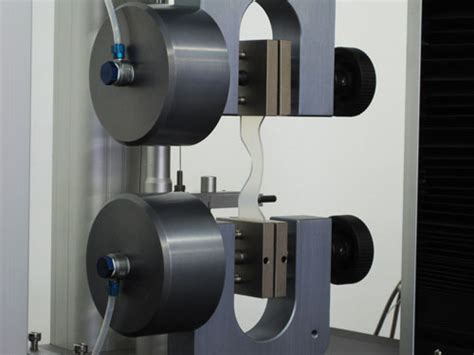

ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test. 5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action.

ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials. These tests are conducted to examine and evaluate the behavior, susceptibility, and extent of resistance of certain materials to sharp-notch tension, tear, axial fatigue, strain-controlled .

Type C (right angle) test piece, divided by the thickness of the test piece.3.2.4 Type T or trouser tear strength—the mean or median force, calculated in accordance with procedures in this method, required to propagate a tear.ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys.1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under conditions that might lead to tearing.Scope. 1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).

The Tongue Tear Test (ASTM D2261) is an essential technique for evaluating the tearing strength of textiles and offers insightful data regarding their resilience to tearing across a range of industries.

vulcanized rubber tear test

tear strength test method

j mitra hiv elisa kit insert

ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test. 5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action.ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials. These tests are conducted to examine and evaluate the behavior, susceptibility, and extent of resistance of certain materials to sharp-notch tension, tear, axial fatigue, strain-controlled .

Type C (right angle) test piece, divided by the thickness of the test piece.3.2.4 Type T or trouser tear strength—the mean or median force, calculated in accordance with procedures in this method, required to propagate a tear.ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys.1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).

A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under conditions that might lead to tearing.

Scope. 1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).

j mitra hcv elisa kit insert

tear initiation strength test

We like to drop used beads into 70% Etoh in a beaker and soak at least overnight or until beaker is full. Then, rinse with diH20 and aliquot into glass culture tubes and autoclave. Glass culture .

astm tear testing|tear initiation strength test